Browse

Dealer

EZGO Motor Upgrade

Upgrade Your EZGO Golf Cart motor for Superior Performance.

Boost the power and efficiency of your EZGO golf cart with our premium selection of EZGO electric motors and controller

upgrades. Whether you need enhanced speed, torque, or the ability to conquer hilly terrain, our wide range of EZGO electric

motors will transform your golf cart into a high-performance machine. We offer DC & AC EZGO electic motors for all models, including EZGO

TXT, RXV and PDS. With high torque EZGO motors and high-speed controllers, you'll experience better acceleration, smoother

rides, and superior battery life. Upgrade with ease using our easy-to-use choose a motor tool.

Click here to Choose

Made in the USA

"If it ain't blue, it ain't red, white, and blue"

Fast Shipping

96% of our products ship within 24 Hours

Low Prices

Similar product cheaper? We'll match

Popular Options

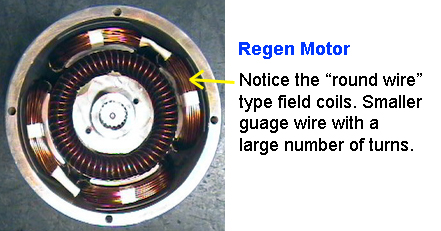

DC - Regen / Sepex

Regen vs Series

Use our Custom Motor Tool for a Warranty!

Buy NowAC Motors

Why AC Motors?

AC EZGO motors represent the next step in electric drive technology. Unlike traditional DC EZGO motors, they deliver higher efficiency, meaning more of your battery power gets converted into usable energy — giving you longer run times on a single charge. Drivers notice smoother acceleration and more consistent performance thanks to instant torque response. On top of that, EZGO AC systems typically require less maintenance because they have fewer wear parts such as brushes.

Applications

Our EZ GO AC motors are engineered to perform across a wide range of vehicle types and terrains: Golf Carts – EZGO RXV models can be upgraded with AC golf cart motor power for more speed, better hill-climbing, and extended range. By expanding into AC golf cart motor technology, we’re providing our customers with a one stop motor shopping experience.

AC Motor Lineup – Coming Soon

If you would like us to email you our EZGO AC motor product line offering once it is available, just click the button below

AC Motors Release Info

Our new AC Motor lineup is expected to launch in Fall 2025. Stay tuned for updates and early access offers.

(5 easy ways to tell the difference - Use at least 3 of 5 to confirm.) |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||

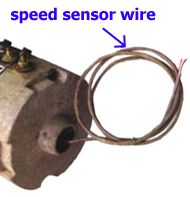

Fig 1.1 |

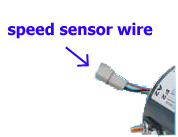

Fig 1.2 |

Fig 1.3 |

||||||||||||||||||||||

EZ-GO Run/Maintenance Switch |

Club Car Tow/Run Switch |

Yamaha Tow/Run Switch |

||||||||||||||||||||||

|

||||||||||||||||||||||||

Fig. 2

Exception: Early EZ-GO - DCS (Drive Control System) models

around 1997 are Regen but do NOT have a speed sensor! |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

Fig. 3a  |

||||||||||||||||||||||||

Fig. 3b  |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

Fig. 4 |

|

|||||||||||||||||||||||

| 5. Series Vehicle Features a. E-Z-GO Series Cart Features.

b. Club Car Series Cart Features.

|

||||||||||||||||||||||||

EZ-GO Motors

Disclaimer: Vehicle performance specs are compared to the standard factory performance. Several factors can effect the performance. Some are battery conditions; tire size, tread type and air pressure; and varying environmental conditions. Standard factory speeds normally run about 14 MPH!!! All vehicle speeds noted are calculated on flat ground. Adding Larger tires normally adds between 2-3 MPH. If you are unsure of how to use the above chart, please call (315) 701-0635. If you do not see the performance you require, please call. We often are capable of making non-standard motors through our engineering department.

Resources and Documents

For more help, call 315-701-0635

EZGO Motor Information

EZGO Motor Selection

From EZGO DCS motors to EZGO PDS motors, we provide a complete range of replacement EZGO electric motors for your golf cart. Whether you're looking for EZGO high-speed electric motors or a rebuild for your EZGO electric motor, we've got you covered. Our EZGO electric motors are available for electric cart performance upgrades, including high torque and high-speed options for any terrain.

Why Upgrade Your EZGO electric Motor?

Upgrading your EZGO golf cart electric motor is the easiest way to enhance your cart’s overall power and efficiency. Whether you're seeking more speed, better hill-climbing capabilities, or improved torque for off-road conditions, our EZGO electric motors are designed to provide a significant performance boost. Enjoy better throttle response, faster acceleration, and increased efficiency on all types of terrain.

DC and AC EZGO Motors for Every Terrain

Our selection of DC and AC EZGO electric motors is designed for the demanding needs of your EZGO electric golf cart. Whether you need an EZGO AC electric motor for improved efficiency, smoother acceleration, and longer run times, or a DC EZGO electric motor for reliable performance, we offer a variety of options that ensure the EZGO motor provides the power you need for any terrain.

Optimized EZGO electric Motors

Our EZGO electric motors are engineered to deliver the best performance, whether you want a EZGO electric motor for higher speed, more torque, or greater efficiency. Whether upgrading for better acceleration, enhanced hill-climbing power, or more reliable performance, our EZGO electric motors will elevate your driving experience.

Trusted EZGO Motor Provider

We are a trusted provider of EZGO motors, all Made in the USA, and committed to delivering high-quality products that improve your EZGO golf cart's performance. Our EZGO motors ensure your vehicle operates at peak efficiency, delivers optimal power, and provides a better driving experience.

EZGO Motor FAQ

Questions Index

Click any question below to jump to its answer:

Answers

Do D&D Motors work on 36V and 48V golf carts?

All D&D golf cart motors work on 36V and 48V golf carts. After converting a golf cart from 36V to 48V the performance gain from a standard EZGO, Club Car, or Yamaha model is normally around 3-4mph. For 72V and other voltages, give us a call.

Do I have a Series or Regen motor?

Please follow the slides to determine if your cart is Regen or Series. For security to be certain, confirm with at least 3 methods: Check for Tow/Run switch (Regen), Speed sensor presence (Regen), Shunt/Round field coil (Regen), or 2 small + 2 large terminal bolts (Regen). You can also contact us at 315-701-0635 for assistance.

The speed sensor on a D&D motor doesn't connect to my golf cart speed sensor cable. What should I do?

You will need to cut off the connector at the end of the speed sensor on the D&D motor and strip the 3 wires. The wires on the D&D motor are Red, Green, and Black. Strip the insulation from the 3 wires coming from the vehicle connector. Once this is done, twist together all wires with matching colors (ex. Red motor speed sensor wire with Red golf cart wire) and cover the exposed wire with electrical tape. If there is one mismatching wire color on the motor and golf cart, connect those two together, those will be your ground wires.

What to do if I can't get my old motor off the transaxle?

We recommend buying "PB Blaster Penetrant" to loosen up any corrosion or other issues stopping the motor from disconnecting. This can be purchased for about $10 from Home Depot. Once purchased, spray liberally on the drive end head and mounting bolts of the old motor and wait 8 hours before attempting to remove the motor again.

What voltage are the batteries in my Golf Cart?

Golf cart batteries are either 6 volt, 8 volt, or 12 volt. You can tell the voltage based on how many water holes your battery has on the top. Multiply your battery voltage by the number of batteries in your golf cart to find your golf cart voltage.

• 3 holes = 6 volts

• 4 holes = 8 volts

• 6 holes = 12 volts

How can I determine what mounting pattern and shaft type I need for my Golf Cart motor?

The "Choose a Motor Tool" accounts for shaft type and mounting pattern when providing motor options. Mounting pattern and shaft are unique for each golf cart brand, so we recommend customers use the Choose a Motor Tool to provide a good buying experience and correct motor options.

Why are my forward and reverse controls flipped after motor installation?

This sometimes occurs when installing a D&D motor to replace an older motor. To fix this, swap the motor connections on the A1 and A2 terminals.

What batteries should I buy for my golf cart?

You need to purchase batteries that have a maximum discharge of 500 amps. The type of battery (Lithium, Lead-Acid, etc.) is independent of Max Discharge. Navigate to our "Beginners Guide to Motors" for more details about batteries.

My old motor had a rubber insert in the shaft, does my D&D motor need this?

No. D&D motors use higher quality shafts made in the USA. This allows our motors to run quietly without an additional rubber insert.

How do I upgrade my V-Glide controller to a solid state controller?

Upgrading a V-Glide controller to a solid state controller will take a few hours and can be a bit complex, but it will increase your max controller amps from 200 to the max amps of the new controller (up to 600 amps). Your performance will increase significantly. We recommend following our youtube video walkthrough explaining exactly how to do this process.

Why are new high performance Golf Cart Motors better than 3rd party refurbished motors?

There are a multitude of reasons behind buying new high performance golf cart motors over 3rd party ones. Mainly when it comes to better performance, reliability, greater efficiency, longer lifespan, and most importantly how customizable it is. A newer motor can be sorted out and customized to what you need for your vehicle setup, performance, and application.

What is a DC Motor?

A DC motor is an electric motor that runs on direct current (DC) electricity. DC motors can operate directly from rechargeable batteries, providing the motive power for electric vehicles. The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary magnets, and rotating electrical magnets. Advantages include low initial cost, high reliability, and simple control of motor speed.

What Is a Shunt or Regen or SEPEX Motor?

The shunt motor is different from the series motor in that the field winding is connected in parallel with the armature instead of in series. The shunt winding is made of small-gauge wire with many turns. Since the shunt field coil is made of fine wire, it has very low starting torque but excellent speed control. The speed can be controlled by varying the amount of current supplied to the shunt field or controlling the current to the armature.

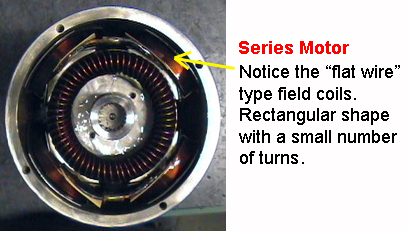

What Are Series DC Motors?

In a series motor, the field winding is connected in series with the armature winding. This motor provides high starting torque and is able to move very large shaft loads when first energized. The field is made from heavy-gauge wire that can carry large amounts of current. Series motors are ideal for applications requiring high starting torque like hoists, cranes, and starter motors.

Pros and Cons of Using Series vs Seperately Excited (SEPEX) DC Motors

Series Motors: High starting torque, simple design, self-regulating speed, low cost. However, poor speed regulation, runaway risk, limited reversibility.

SEPEX Motors: Excellent speed control, stable operation under load, easier reversibility, better efficiency at variable loads. However, more complex and costly, lower starting torque, additional control components needed.

How Does An Electric DC Motor Work?

The electric DC motor has two basic parts: the rotating armature and the stationary field coils (stator). The armature is made of coils of wire wrapped around the core with an extended shaft that rotates on bearings. The ends of each coil terminate at the commutator where brushes make electrical contact. When voltage is applied, current flows through the field and armature windings creating magnetic fields that cause the armature to rotate through magnetic attraction and repulsion.

How can I make my golf cart faster?

There are several ways to make your golf cart faster: upgrade to a high speed golf cart motor, upgrade to a high speed controller, increase the diameter of your tires, increase the voltage from 36V to 48V, or increase the gearing of your cart. Each method has different benefits and considerations for performance improvement.

Upgrade to a high speed golf cart motor

Upgrading to a high speed motor is one of the most effective ways to increase your golf cart's speed. High speed motors are designed to operate at higher RPMs while maintaining torque and efficiency. This upgrade typically provides the most significant speed improvement compared to other modifications.

Upgrade to a high speed controller

A high speed controller can increase your cart's performance by providing more current to the motor and better speed regulation. Modern controllers offer programmable features, regenerative braking, and improved efficiency. When paired with a high performance motor, a quality controller maximizes your speed and performance gains.

Increase the diameters of my tire

Increasing tire diameter effectively increases your golf cart's top speed by covering more ground per revolution. However, this modification may reduce acceleration and torque, especially on hills. It's important to balance tire size with your motor's capabilities to avoid overloading the system.

Increase the voltage of my cart from 36V to 48V

Converting from 36V to 48V typically increases speed by 3-4 mph and improves overall performance. This requires replacing your battery pack and ensuring your motor and controller are compatible with 48V operation. The voltage increase provides more power to the motor for better acceleration and hill climbing.

Increase the gearing of my cart

Changing the gear ratio in your differential or using different motor mounting can alter your cart's speed characteristics. Lower gear ratios increase top speed but reduce torque, while higher ratios improve acceleration and climbing ability but limit top speed. This modification requires mechanical expertise and may affect other performance aspects.

How is speed controller in a DC motor?

Speed control in a DC motor can be achieved through several methods: varying the armature voltage, controlling the field current, or using pulse width modulation (PWM). Modern electronic controllers use PWM to efficiently control motor speed by rapidly switching the power on and off, providing smooth speed control and improved efficiency.

Pros and Cons of Gas vs Electric Motors

Electric Motors: Quiet operation, instant torque, low maintenance, environmentally friendly, lower operating costs. However, limited range, charging time required.

Gas Motors: Longer range, quick refueling, higher top speeds possible. However, louder operation, more maintenance required, emissions, higher operating costs.

How to test your golf cart motor for a short

To test for a short in your golf cart motor: 1) Disconnect all wiring, 2) Use an ohmmeter to test resistance between terminals, 3) Test each terminal to the motor frame/ground, 4) Check for continuity in windings, 5) Look for burned or damaged wiring. Very low resistance readings or connections to ground indicate a short circuit that requires motor repair or replacement.

4 AWG golf cart wire kits specifications

4 AWG wire kits are designed for high-current golf cart applications. These kits typically include appropriately sized cables for battery connections, motor connections, and controller wiring. The 4 AWG wire can handle the high current demands of golf cart motors while minimizing voltage drop and ensuring safe, reliable operation.

EZGO Technical Tips

Technical Tips Index

Click any tip below to jump to the detailed explanation:

Technical Solutions

Increase the efficiency of a DC motor

There are quite a few things to you can do to increase the efficiency of a DC motor. Here are a few of them:

Maintenance: Regular inspections, lubrication, and the cleanness of your motor can all have an impact. Always make sure your motor is as clean as possible and that its components don't have too much wear and tear. This includes things such as its brushes and commutators, as well as electrical connections and insulation.

Temperature management: The name of the game is keeping cool. High heats can cause damage to your motor. The key to keeping a motor cool is to choose a motor with enough steel and copper. This can be done by using our "Choose a Motor Tool". If possible we recommend using ventilation, internal or external fans, or a heatsink.

High Quality Components: Look for high quality copper windings, bearings, and lubricants. As well as high quality electrical steel in the laminations with minimal core loss.

Keep the rotor and stator close together: Precision is key, keeping a small gap between the rotor and stator without letting them touch can increase efficiency.

Disassemble a golf cart axle

We understand sometimes you need to dive into the finer details. Disassembling a golf cart axle can be tricky, but we're here to help. Follow the step-by-step guide below:

Tools you'll need:

• Wheel Chocks

• Car Jacks

• Jack Stands

• Socket Set

• Ratchet

• Needle-Nose Pliers

• Bearing Puller

Steps:

1. Park the golf cart on a flat surface. Place wheel chocks in front of the front wheels. Jack up the rear end and set jack stands underneath.

2. Remove the bolts holding the rim onto the hub and pull off the tire and rim.

3. Take off the cover of the drum brake and remove the bolts securing it to the hub.

4. Use needle-nose pliers to pull out the "C" clip through the hole in the flange. Pull the hub away from the axle.

5. Attach the bearing puller to the center of the axle and secure its arms around the rear bearing housing. Tighten until the bearing comes free.

6. Finally, pull the axle out of the golf cart by hand.

Reset Onboarding Computer (OBC) of a series motor

1. Unplug the positive and negative connections from the battery pack

2. Put the cart to reverse

3. Push the accelerator pedal fully down until the reverse buzzer ceases

4. Reconnect the power supply

Speed Sensor Test Procedure: Cart is starting fast but slows down quickly

Ensure that the cart is not in sleep mode. You can do this by driving the cart a short distance. With the F&R switch set to any of the three positions and the Tow/Run switch in the Run position, manually push the cart to simulate a roll-away situation. The "Roll-Away" braking system will engage to slow the cart down and prevent it from rolling away, accompanied by a series of beeps from the reverse buzzer as it decelerates. If the cart rolls freely without any resistance, this indicates a lack of communication between the cart's speed sensor and the controller. In this case, there is a speed sensor failure, and it will need to be replaced.

Diagnose a golf cart with a malfunctioning controller

The issue with a non-running diagnosis lies in identifying the cause versus the effect. The root of the issue is often the motor. A motor that is shorted, even partially, can lead to controller failure. Installing a new controller with a faulty motor will likely cause another failure.

Testing a Regen/Shunt-Wound Motor:

1. Discharge the controller circuit

2. Disconnect F1 and F2 from the controller

3. Disconnect all cables from the motor

4. Use an ohmmeter to test:

- A1 to A2: Any reading other than "open" is acceptable

- F1 to F2: Reading between 1 and 3 ohms is acceptable

- Any continuity from studs to case indicates a problem

5. Remove the motor to inspect windings and brushes

Even if the motor passes all tests, it may still be defective. If it fails any test, it's likely shorted and will damage a new controller.

How to check your Golf Cart for a bad Solenoid

On a typical solenoid there are four terminals - usually two large and two small. Battery voltage is applied to the two small terminals to activate the solenoid which connects the two large terminals together.

Testing Steps:

1. Disconnect cables from the two large terminals and wrap cable ends in tape

2. Set voltmeter to OHMS and place probes on each large terminal

3. With key off and cart in neutral, there should be no reading

4. Put cart in forward, key on, step on accelerator - you should hear a click

5. If you hear a click, test resistance between large terminals - should read 0 to 0.4 ohms

6. If no click, test voltage between small terminals with key on, cart in forward, accelerator pressed - should see full battery voltage

If you see full battery voltage but no click, the solenoid coil has failed. If meter reads 0, there's a problem elsewhere in the cart.

How do I tell if my Golf Cart Solenoid is not working

A Golf Cart Solenoid is nothing more than a switch activated by external electrical input. It has two basic circuits: Primary (activation circuit) and Secondary (power circuit).

Testing Process:

A) Does the solenoid make a "clicking" sound?

If not, check if activation voltage is present at small terminals. Connect voltmeter across connections and activate the system (run mode, key on, forward, accelerator pressed). If you read system voltage but no click, the solenoid is defective.

B) No click and no system voltage:

This means one voltage potential is missing. Test each potential separately to determine which is missing - could be key switch, micro switches, wiring, or ground connection.

Secondary Circuit Testing:

If solenoid clicks but cart won't run, disconnect cable from load terminal and test for voltage. No voltage indicates defective contacts; voltage present means the problem is in controller, motor, or wiring.

How do I troubleshoot my Solenoid

Follow systematic troubleshooting based on symptoms:

Safety First:

• Raise rear wheels off ground with proper support

• Disconnect battery when required

• Use caution with higher voltage carts

• Work in well-ventilated area

• Keep flames away from battery compartment

Common Issues:

• If solenoid doesn't click: Check activation voltage at small terminals

• If clicks but cart doesn't run: Test secondary circuit for voltage

• If cart runs constantly: Check for stuck contacts

• If missing voltage: Trace through key switch, micro switches, and wiring

Remember to use correct wiring diagram for your specific cart make, model, and year. Some systems use different voltage configurations or grounding methods.

How to Wire a Golf Cart Battery

Electric golf carts normally run on a bank of six batteries. The batteries are wired in series to provide the correct voltage.

Steps:

1. Open battery compartment by lifting the seat

2. Remove black negative cable first, then positive wire from each battery (front to rear order)

3. Lift out batteries requiring replacement (remove securing brackets if needed)

4. Place new batteries in same positions and re-secure brackets

5. Reconnect cables: Main positive lead connects to first battery positive terminal

6. Connect cable from first battery negative to second battery positive

7. Continue connecting negative to positive until all batteries are connected

8. Last battery negative connects to frame/golf cart controls

9. Connect reverse positive cable to any positive terminal on the battery bank

This series wiring provides sustained charge for propulsion throughout a playing day.

Maintaining your cart for maximum performance

Regular upgrades to your D&D Motor Systems motor can drastically improve the results of your cart. Proper maintenance includes regular inspections, keeping components clean, proper lubrication, and ensuring all electrical connections are secure.

Sticking or dragging brakes

Caused by dirt in brake cable housings, dust or oil on brake shoes, affecting brake release. Clean cable housings and brake components, replace oil-contaminated brake shoes as needed.

Improper wheel alignment

Wheels should have 1/4-inch toe-in; the distance from the front should be slightly shorter than the back to ensure proper alignment. Adjust tie rods to achieve proper alignment.

One or more weak batteries

Batteries need the correct water level (1/4 inch above plates) and should be checked with a load tester to ensure consistent performance across all batteries. Replace weak batteries to maintain proper cart performance.

Bad, worn or loose battery cables

Corroded or worn battery cables should be cleaned or replaced, as they can disrupt battery function. Ensure all connections are tight and free of corrosion.

Dirty F&R switch

Clean or replace the F&R switch if contacts are dirty, as it can affect performance. Dirty contacts can cause intermittent operation or poor connection.

Improperly Adjusted V-glide linkage

Ensure the V-glide wiper brush reaches its full range when the accelerator is pressed and is level on contact pads. Proper adjustment is critical for smooth operation.

Wheel bearing drag

Bearings should be clean and well-greased without overtightening to avoid wheel drag. Overtightened bearings can cause excessive friction and reduce performance.

Leaking axle seals

Oil leaks onto brake shoes can cause dragging; replace seals and clean or replace shoes as needed. Leaking seals can contaminate brake components and cause performance issues.

Improper tire pressure

Underinflated tires (run at 25 psi) can reduce cart speed, so keeping proper tire pressure is essential. Check tire pressure regularly and maintain recommended PSI.

Overheating motor

Lack of airflow can cause motor overheating, leading to insulation breakdown; adequate airflow keeps it cool. Ensure ventilation is not blocked and motor housing is clean.

Bad motor bearings

Worn bearings can cause armature drag, leading to excess noise and reduced performance. Replace worn bearings to restore smooth motor operation.

EZGO Installation Videos

Installation Tutorials

DC Motor Club Car Installation

Learn how to install a D&D DC motor in Club Car golf carts. Covers mounting patterns, wiring connections, and performance testing.

DC Motor EZGO Installation

Complete step-by-step installation guide for installing a D&D DC motor in an EZGO golf cart. This video covers motor removal, installation, wiring connections, and testing procedures.

EZGO Photo Gallery