Browse

Dealer

Electric Car Conversion Motors

D&D Motor Systems is the premier manufacturer motors in the U.S., specializing in gas to electric car conversions. Our high-performance electric car motors offer

superior torque, enhanced thermal capabilities, and a competitive price, all while being proudly made in the USA.

Whether you're looking for an electric car motor for sale, a best-in-class EV motor, or a reliable motor for an

electric car conversion, we have you covered.

Additionally, we offer a complete line of U.S. made 72V electric DC controllers designed specifically for use with

our DC electric vehicle motors. Explore our products for your DIY electric car conversion kit, gas to electric car

conversion, or even a VW Bug EV conversion project.

Lower Performance

|

Part Number: 170-004-0003 (Series)

Description: This EV Motor is good for small cars weighing between 800 - 1500 lbs and looking for low performance. Good for someone looking for a low cost option to commute a short distance to and from work or to just run short errands around town. Vehicle designs usually are between 48 and 96 Volts.

|

EV Car Motors Specifications

| Design Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Full Load Weight (lbs) | Voltage | Gear Ratio | Batteries/ Usable energy | Tire Size (Inches) | |||

| 800 | 72 | 3 | 5.4 KWh | 19 | |||

| 1100 | 72 | 3 | 5.4 KWh | 19 | |||

| Motor Performance and Characteristics | ||||||

|---|---|---|---|---|---|---|

| PS | HP (Peak | Continuous) | Max Efficiency | Enclosure | |||

| 6 | 18.5 | 8.5 | 83 | Vented | |||

| 6 | 18.5 | 8.5 | 83 | Vented | |||

| Vehicle Performance | |||

|---|---|---|---|

| Top Speed (mph) | Contoller Amperage (Amps) | Acceleration | Range (Miles) |

| 60 | 600 | Moderate | 20-50 |

| 60 | 600 | Low to Moderate | 15-40 |

Other Available Motor Options: Low/Medium Performance Motor Options

High Performance

|

Part Number: 170-015-0004 (Series)

Description: This EV Motor is good for small cars weighing between 1000 - 1800 lbs and looking for medium performance. Good for someone looking for a mid range cost option to commute a short distance to and from work or to just run short errands around town while getter better performance than our 170-015-0004 option. Vehicle designs usually are between 72 and 144 Volts.

|

EV Car Motors Specifications

| Design Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Full Load Weight (lbs) | Voltage | Gear Ratio | Batteries/ Usable energy | Tire Size (Inches) | |||

| 2000 | 72 | 3 | 5.4 KWh | 19 | |||

| 2000 | 96 | 3 | 7.2 KWh | 19 | |||

| 2000 | 120 | 3 | 9.0 KWh | 19 | |||

| 2000 | 144 | 3 | 10.8 KWh | 19 | |||

| Motor Performance and Characteristics | ||||||

|---|---|---|---|---|---|---|

| PS | HP (Peak | Continuous) | Max Efficiency | Enclosure | |||

| 16 | 19 | 8.4 | 86.5 | Vented | |||

| 16 | 30.4 | 10.2 | 85 | Vented | |||

| 16 | 37.3 | 12.4 | 84 | Vented | |||

| 16 | 43.8 | 14.6 | 82.4 | Vented | |||

| Vehicle Performance | |||

|---|---|---|---|

| Top Speed (mph) | Contoller Amperage (Amps) | Acceleration | Range (Miles) |

| 70 | 600 | Low | 10-20 |

| 70 | 600 | Moderate | 14-25 |

| 70 | 600 | High | 17-35 |

| 70 | 600 | High | 20-45 |

Other Available Motor Options: High Performance Motor Options

Need a Custom Car Motor?

1. Why build an EV?

Today there are limited production electric vehicles (EVs) available, so

converting an existing internal combustion engine (ICE) vehicle to an electric vehicle (EV)

might be the best choice available to obtain an EV. Building your own electric vehicle

(EV) can be a rewarding and challenging experience. Not only will you be a pioneer in the

EV movement, but you will also be recycling a car that may be headed for the junk yard. Don’t

wait for Detroit. Custom build an EV yourself. A typical EV conversion will

achieve a range of 30-60 miles per charge. Studies show 80% of commuters travel less than 40 miles per day,

making a gas to electric car conversion a practical solution for daily use.

EVs are a clean, efficient alternative to conventional vehicles – using readily available

electric car motors, often included in a diy electric car conversion kit.

EV motors produce zero emissions and, over the full fuel cycle, are up to 99% cleaner than

gasoline and diesel vehicles. Electric car engine owners enjoy significantly lower fuel and

maintenance expenses. Finally, EVs help reduce our dependence on oil.

D&D Motor Systems does not provide

complete electric vehicle (EV) conversion kits. We only provide the motor

and controller—ideal for those looking for the best electric motor for car

conversion or standalone electric car motors for sale. To obtain complete kits

or other components go to our

Links

section and look under EV

Conversions for potential suppliers.

2. What basic steps are involved

- Define the purpose of the vehicle:

- Why do you want an EV?

- Where will you drive it?

- Who else will drive it?

- How many miles do you require on a daily basis?

- How often will you drive the vehicle?

- With or Without passangers?

- Will your employer allow you to charge at work?

- How much do you want to spend?

- How much time do you have for the conversions?

- Evaluate the vehicles manufactured.

- Sports cars, such as the Honda CRX, Pontiac Fiero, Toyota MR2, Porsche 914, Fiat X-19, Nissan Pulsar, MGB or MG Midget. Sports cars have limited space and minimal payload capacity.

- Passenger cars and vans, such as the Ford Escort, VW Rabbit, VW Beetle, Saturn, Honda Civic and Geo Metro. The payload capacity for a Geo Metro is about 600 lbs.

- Select a Vehicle to Convert

- Look for an EV kit for the vehicle you choose

- Familiarize yourself with the EV parts

- Safety Testing

Ask yourself the following questions:

When you start to evaluate the different vehicles, you will find there are mainly 2 classes out there:

Each of these classes have their own characteristics with respect to aerodynamic drag, curb weight, Gross Vehicle Weight Rating (GVWR), passenger compartment, and available space for batteries. Table 1 lists typical vehicles under each of these classes and their range using various lead acid battery packs (6V and 12V). Range is a function of battery weight because the battery represents the fuel. Typically it takes 15-20 lbs of lead to achieve 1 mile in range. A Rule of Thumb is that 1/3 of the EVs weight should be batteries; the other 2/3 represents dead weight (i.e. frame, suspension, body, motor, etc). If you could decrease this dead weight to 1/2 leaving 1/2 for fuel, you would have superior performance.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Other Considerations:

Front Wheel Drive(FWD) vs Rear Wheel Drive (RWD)

A FWD vehicle has the advantage of being more efficient, improving range in most electric car motor setups. However, front-wheel-drive vehicles often have smaller engine compartments, limiting battery placement. Also, FWD vehicles require more weight on the front axle. Rear-weighted EV motor systems in RWD cars may offer better handling in snow or rain, as seen in classic VW Bug EV conversions.

High-voltage, high-amperage EV motors can produce more torque than the original ICE engine. For smaller FWD cars, this can lead to traction issues. That’s why diy electric car conversion kit users often prefer RWD platforms for better weight distribution and handling.

Manual Vs. Automatic Transmission

Most EV conversion vehicles use manual transmissions, which are more efficient than

automatics. Manual transmissions require less torque from the electric car motor, extend

driving range, and eliminate the need for a cooler. Because most electric car motors operate

efficiently at 4000–5000 rpm, automatics—which shift around 2000 rpm—aren’t ideal. If you're working on a

diy EV motor project, we recommend switching to manual.

Power Brakes

As your vehicle gains 800–1200 lbs from the EV conversion parts (e.g., dc motors for

cars and batteries), power brakes are recommended for safety. Curb weight and GVWR

become key when selecting a donor vehicle for your gas to electric car conversion.

For example, a Geo Metro is light but has a low payload capacity. While it’s a popular platform for hobbyists, heavier systems like those using NetGain Motors or high-performance EV motors may strain the vehicle's frame. Always check weight distribution, especially with onboard chargers and battery box placement. Rear-heavy layouts, such as in a VW Bug EV conversion, can improve snow handling.

These kits make the process easier and include all components except batteries. A typical diy electric car conversion kit costs between $3,000 – $6,000. Battery costs vary from $700 – $4,000 based on size and chemistry.

From electric car motors for sale to chargers and wiring, knowing your system is essential. Many users prefer kits with dc motors for cars for simplicity and affordability.

Test the EV motor setup, charger, and connections. Once complete, enjoy the quiet ride and performance. Whether you’re using parts from NetGain Motors or your own custom design, your diy EV motor setup will deliver a cleaner, more efficient drive.

3. How much does it cost to complete a typical conversion

Obviously this firstly depends greatly on the vehicle you looking to convert and what you pay for that vehicle. Secondly, the overall performance and range you require in your application are major price effectors. With that said, the range could be anywhere from $4,500 to $11,500 typically.

4. How much will I save on gas?

| Vehicle Type | Description | Details |

|---|---|---|

| Gas Guzzler | Mileage | 20 miles/gallon |

| Cost Per Gallon | $4.00 (US Average) | |

| Cost Per Mile | $0.20 / mile | |

| Clean Electric | Electricity Cost | $0.07 / kWh |

| Recharge Cost | Approx. $0.84 / charge (12 kWh) | |

| Vehicle Range | Approx. 50 miles / charge | |

| Cost Per Mile | 1.68 cents / mile | |

| Savings | Savings Per Mile | $0.1832 / mile |

| Annual Miles Driven | 12,000 miles / year | |

| Annual Savings | $2,198.40 / year | |

| Note: Annual savings do not include reduced maintenance costs. You could save even more! | ||

5. What are the most popular EV conversion vehicles

|

|

|

|

|

|

6. What driving range can I expect per charge

Of course it all depends on the conversion – vehicle type along with the number and type of batteries. However, most people who drive electric street vehicles say they get between 30 and 60 miles per charge, without saying what they mean by charge. I believe it is only reasonable to state the range based on a 50% drop in charge capacity. You can go lower, but repeatedly going down to 40% and less capacity (remaining capacity) point will shorten the life of the batteries. Keep in mind that driving habits impact distance. For more detailed information regarding vehicle range, go to FAQ #2 - Section B, above.

7. How fast will my converted EV go

Depending upon your vehicle type, set-up and application the average top speed is anywhere between 30 - 70 MPH (miles per hour)

8. How do electric cars work

Electric cars are powered by electric car motors instead of traditional gasoline engines. These EV motors—often DC motors designed specifically for cars—are gaining popularity due to their efficiency and environmentally friendly nature. Whether you're considering a gas to electric car conversion or buying a factory-made EV, the core components work similarly.

- Electric cars create less pollution than gasoline-powered cars, so they are an environmentally friendly alternative, especially in cities.

- Any news story about hybrid cars often includes electric vehicles as well.

- Vehicles powered by fuel cells are also electric cars, and they are getting a lot of attention in the news.

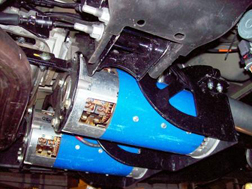

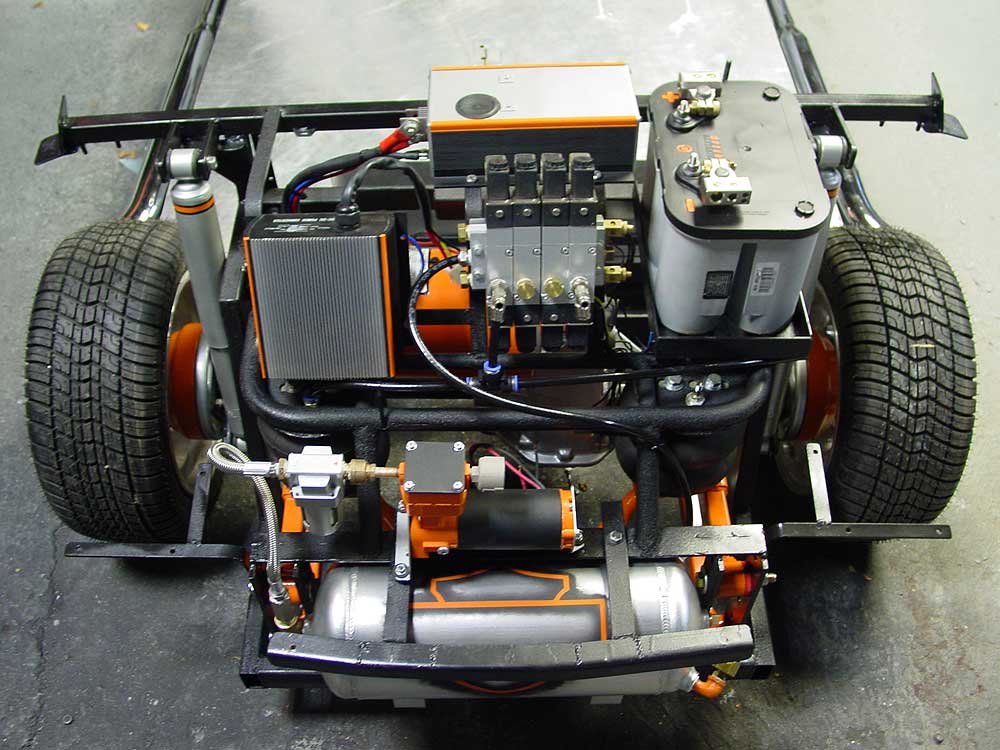

From the outside, many electric vehicles (EVs) look identical to gasoline cars. Most electric vehicles use custom or converted electric car motors—commonly sourced from EV motor manufacturers like NetGain Motors or adapted from dc motors for cars. When undergoing an EV conversion or using a DIY electric car conversion kit, these motors replace the gas engine.

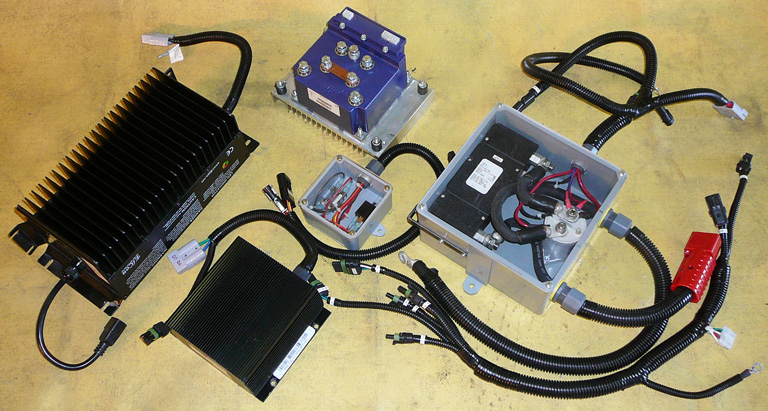

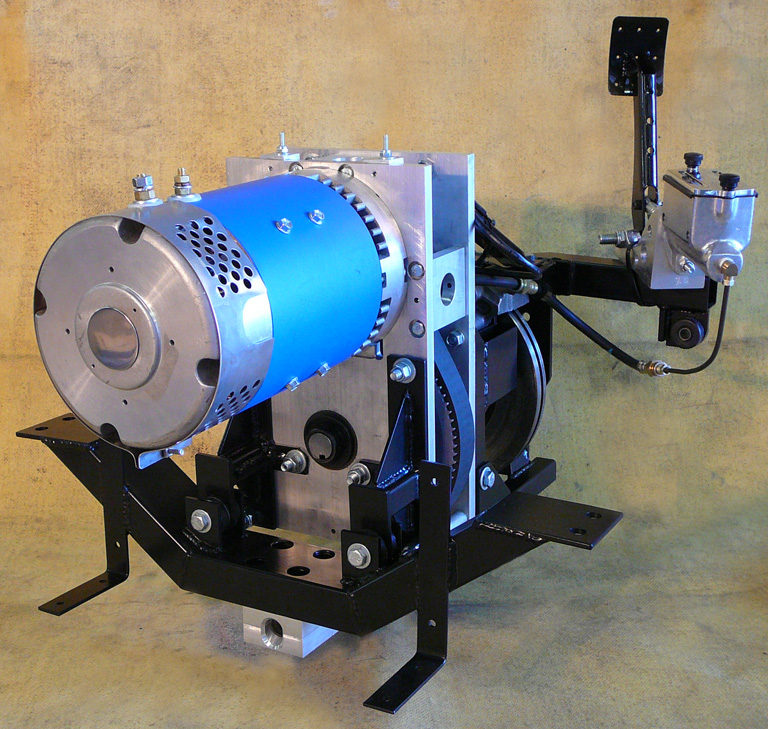

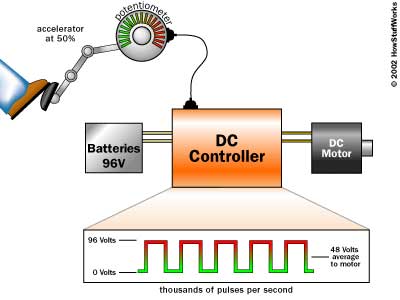

- The gasoline engine is replaced by an electric motor, often a high-torque EV motor.

- The electric motor gets its power from a controller.

- The controller receives power from a pack of rechargeable batteries.

Inside an Electric Car

- The electric motor (sometimes from brands like NetGain Motors, popular in VW Bug EV conversion projects)

- The motor controller

- The battery pack (usually lithium-ion today)

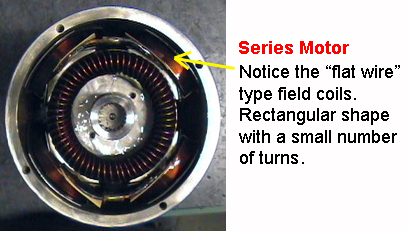

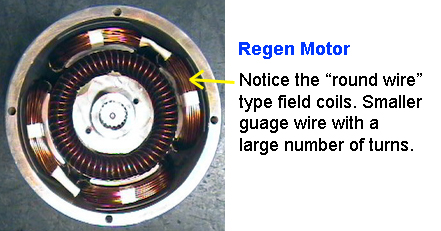

A simple DC controller connected to batteries and a DC motor. This setup is often seen in DIY EV conversion kits and popular among enthusiasts looking to convert car to electric with components like electric car motors for sale online.

The controller manages power delivery based on input from the accelerator pedal, converting pedal position into voltage sent to the motor. In DIY EV conversion projects, hobbyists often use repurposed components or commercial kits featuring the best electric motors for car conversion.

Most DC motors used in EVs are adapted from industries like forklifts, making them affordable and reliable for DIY EV motor builds. For example, a 20,000-watt motor in a converted car can temporarily output over 100,000 watts, giving excellent acceleration potential, especially in a small car like a VW Bug converted to electric.

Batteries, while improving, remain a limiting factor. Many DIY EV builders explore modern lithium-ion packs as part of their gas to electric car conversion, using lightweight, high-capacity cells for better range and performance.

9. How do I measure State-of-Charge of my batteries

Voltage Method

Measuring the state-of-charge (SoC) of your EV's battery is crucial for monitoring performance—especially in gas to electric car conversions or vehicles using a DIY electric car conversion kit. The most common approach is the voltage method. While simple, it can be unreliable depending on battery chemistry and temperature.

This method works reasonably well with lead-acid batteries—commonly used in dc motors cars or entry-level electric car motors. However, for lithium-based packs (frequently found in modern EV conversions or electric car engines), the voltage profile is flat, making precise SoC readings difficult unless the battery has been at rest for hours.

In custom builds, such as a VW Bug EV conversion or projects using NetGain Motors, accurate SoC monitoring becomes essential to avoid battery damage. Without a solid SoC reading, the full potential of high-performance EV motors can't be used efficiently.

It’s important to let the battery rest (ideally 4–24 hours) before taking an open circuit voltage (OCV) reading. This is especially vital in performance builds using lithium-ion batteries or in any convert car to electric setup that includes large packs.

10. How can I get more range out of my EV

- Maintain Your Car – Whether you’re driving a factory EV or a DIY electric car conversion, proper maintenance is key. Keep tire pressures optimal to reduce rolling resistance and ensure your electric car motor, controller, and battery pack remain cool—especially in custom builds using NetGain Motors or other performance EV motors.

- Drive Accordingly – Use smooth acceleration and avoid aggressive driving. DIY EV conversions, particularly those with dc motors for cars, benefit greatly from conservative driving habits, preserving battery life and maximizing range.

- Adjust Charging Time – Don’t let your vehicle sit fully charged overnight. Especially true for custom lithium-ion systems in diy electric car conversion kits, prolonged full charges can accelerate battery degradation. Time your charge to finish just before driving to improve both battery health and daily range.

11. How do the EV batteries work and how how much do they typically cost & weigh

- How Electric Car Batteries Work?

- Cost & Weight

- A typical 6V golf cart battery (lead acid) such as a Trojan T-105 with a 2 hour Amp-Hour Rating of 146 will weigh 62 lbs. and cost approximately $140-$150.

- A typical Lithiom-Ion battery used for EV's such as a CALB/SkyEnergy 3.2 V with a 100 Amp-Hour capacity weighs 7.1 lbs and costs about $140-$150. Some Lithium-Ion batteries depending on the brand and model can be 2 to 3 times as much!

A battery is a device for storing chemical energy and converting that chemical energy into electricity. A battery is made up of one or more electrochemical cells, each of which consists of two half-cells or electrodes. One half-cell, called the negative electrode, has an overabundance of the tiny, negatively charged subatomic particles called electrons. The other, called the positive electrode, has a deficit of electrons. When the two halves are connected by a wire or an electrical cable, electrons will flow from the negative electrode to the positive electrode. We call this flow of electrons electricity. The energy of these moving electrons can be harnessed to do work -- running a motor, for instance. As electrons pass to the positive side, the flow gradually slows down and the voltage of the electricity produced by the battery drops. Eventually, when there are as many electrons on the positive side as on the negative side, the battery is considered 'dead' and is no longer capable of producing an electric flow.

Lead-acid batteries, similar to the one shown here, have been used in automobiles since the middle of the 19th century.

The electrons are generated by chemical reactions, and there are many different chemical reactions that are used in commercially available batteries. For example, the familiar alkaline batteries commonly used in flashlights and television remote controls generate electricity through a chemical reaction involving zinc and manganese oxide. Most alkaline batteries are considered to be a disposable battery. Once they go dead, they're useless and should be recycled. Automobile batteries, on the other hand, need to be rechargeable, so they don't require constant replacement. In a rechargeable battery, electrical energy is used to reverse the negative and positive halves of the electrochemical cells, restarting the electron flow.

Automobile manufacturers have identified three types of

rechargeable battery as suitable for electric car use. Those

types are lead-acid batteries, nickel metal

hydride (NiMH) batteries, and

lithium-ion (Li-ion) batteries.

Lead-acid

Advantages: This chemistry has been proven over more than

140 years. Batteries of all shapes and sizes, available in

sealed and maintenance-free products, are mass-produced today.

In their price range, lead-acid batteries provide the best value

for power and energy per kilowatt-hour, have the longest life

cycle and a large environmental advantage in that they are

recycled at an extraordinarily high rate. (Ninety-seven percent

of the lead is recycled and reused in new batteries.). No other

chemistry can touch the infrastructure that exists for

collecting, transporting and recycling lead-acid batteries.

Disadvantages: Lead is heavier compared to some alternative elements used in other technologies; however, certain efficiencies in current conductors and other advances continue to improve on the power density of a lead-acid battery's design.

Lithium-ion

Advantages: It has a high specific energy (the number of

hours of operation for a given weight) making it a huge success

for mobile applications such as phones and notebook computers.

Disadvantages: More expensive than lead. The cost differential is not as apparent with small batteries for phones and computers, and owners of these devices may not realize that they are paying much more per stored kilowatt hour than other chemistries. However, because automotive batteries are larger, the cost becomes more significant. In addition, currently there is no established system for recycling large lithium-ion batteries.

Nickel-metal hydride

Advantages: It is reliable and lightweight. In hybrid

vehicles, these batteries have equal to 100,000 miles.

Disadvantages: The metals in the battery are 25 times more expensive than lead. Nickel has been identified as a carcinogen. Hybrid vehicles have not been on the road long enough to allow the batteries to completely prove their projected cycle life. No significant recycling capability exists.

Note: The Advanced Lead-Acid Battery Consortium has helped to develop and test an advanced lead-acid battery powered system that operates at the partial state of charge demands necessary for a hybrid vehicle and recently equipped a Honda Insight with this system. Advanced lead-acid batteries will challenge the more expensive nickel metal hydride system in hybrid vehicles today.

Lead-acid batteries were invented in 1859 and are the oldest form of rechargeable battery still in use. They've been used in all types of cars -- including electric cars -- since the 19th century. Lead-acid batteries are a kind ofwet cell battery and usually contain a mild solution of sulfuric acid in an open container. The name comes from the combination of lead electrodes and acid used to generate electricity in these batteries. The major advantage of lead-acid batteries is that, they are well understood and cheap to produce. However, they do produce dangerous gases while being used and if the battery is overcharged there's a risk of explosion.

Nickel metal hydride batteries came into commercial use in the late 1980s. They have a high energy density -- that is, a great deal of energy can be packed into a relatively small battery -- and don't contain any toxic metals, so they're easy to recycle.

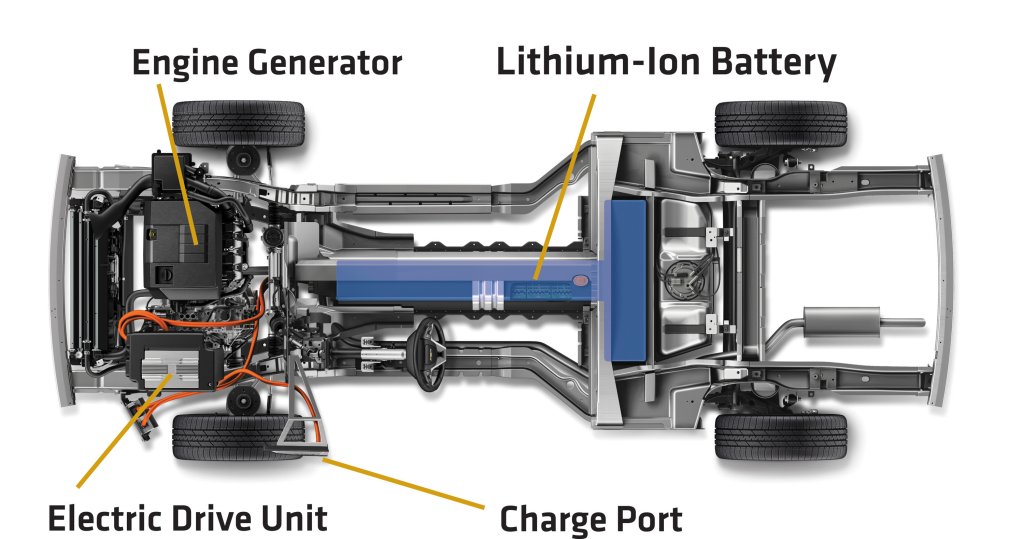

© GM Corp.

This Chevy Volt concept vehicle chassis clearly shows the location of the vehicle's lithium-ion battery pack (in blue).

Lithium-ion batteries, which came into commercial use in the early 1990s, have a very high energy density and are less likely than most batteries to lose their charge when not being used -- a property called self discharge. Because of their light weight and low maintenance requirements, lithium-ion batteries are widely used in electronic devices such as laptop computers. Some experts believe that lithium-ion batteries are about as close as science has yet come to developing a perfect rechargeable battery, and this type of battery is the best candidate for powering the electric cars of the near future. A variation on lithium-ion batteries, called lithium-ion polymer batteries, may also prove valuable to the future of EVs. These batteries may eventually cost less to build than lithium-ion batteries; however, at the present time, lithium-ion polymer batteries are prohibitively expensive.

12. What should I know about battery care

Proper battery care is essential—whether you’re driving a commercial EV or building a DIY electric car using a conversion kit with an EV motor or electric car engine.

- Always fully recharge your battery after use. For any gas to electric car conversion or NetGain Motors setup, timely charging improves battery lifespan.

- Use a trickle charge (10mA) when not in use. This is especially helpful in dc motors cars or those with custom electric car motors for sale via third-party suppliers.

- Never store batteries directly on concrete floors. Elevate them to prevent internal temperature gradients, a common tip in EV conversion circles.

- Avoid deep discharges—don’t let voltage drop below 80% of nominal. Even deep-cycle batteries used in diy EV motor kits don’t like full drains.

Clean batteries regularly with a baking soda solution, and ensure all connections are secure. If you're working on a VW Bug EV conversion or building with the best electric motor for car conversion projects, corrosion and poor connectivity will degrade performance and reduce safety.

Lastly, always use distilled water when topping up fluid levels in serviceable batteries. Taking care of your battery is taking care of your EV motor—and that applies whether it’s a basic setup or a high-end NetGain-powered electric car.

13. Can I use an automatic transmission

Most EV conversions are manual transmissions because they are more efficient than automatic transmissions and provide greater range, require less motor torque, require no transmission cooler, and are easier to convert. The problem with an automatic transmission is that it shifts at about 2000 rpm; the electric motor is usually designed to operate efficiently between 4000-5000 rpm. Consequently, the automatic transmission is a poor choice which results in decreased range. If you buy a vehicle with an automatic transmission, you can replace it with a manual transmission. The additional cost is $150 and up depending on the transmission and used auto parts dealer. Consider trading the automatic transmission.

Made in the USA

The only DC Motors Manufacturer in America

Fast, Reliable Shipping

We provide fast 2-3 day shipping in the USA

Engineering Expertise

Unparallel customer support from our expert engineers